Important Update from the Perma Blend & Tina Davies Family

Dear Perma Blend Family,

We would like to announce that we have made some exciting formulation changes that will improve the color and performance of our pigments. At Perma Blend, we are always striving to advance and evolve in safety, effectiveness, and quality.

With the growing popularity of the permanent cosmetics industry, health and safety regulations in various countries are responding with stricter rules. We abide by ResAp 2008 which is the European Resolution on Tattooing and Permanent cosmetics.

To stay ahead of the curve, we have officially begun to gradually remove Red 210 (CI #12477) from our products and in turn, began to use Red 254 (CI #56110). Red 210 is an AMAZING COLOR and it has been in the tattooing industry for almost 100 years, however moving forward, Red 254 is the safest alternative. Please note, you can still continue to safely use your pigments that include Red 210.

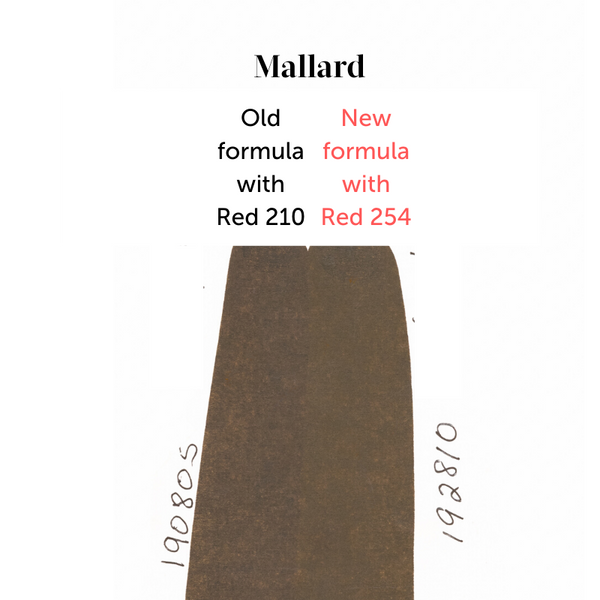

Our chemists are very experienced and have been successful at replicating many of the existing colors with Red 254, however, there are some subtle differences in how our pigments appear in the bottle that may cause concern for artists. Check the label of your bottle to identify Red 210 (CI #12477) and Red 254 (CI #56110).

With the goal of clarifying the reason why the pigments appear different in the bottle vs. outside of the bottle, let’s look at terms that we tattoo ink insiders and our chemists use:

MASSTONE - the color in its most concentrated form and used to describe what a color looks like in a bottle. Gravity pulls some of the denser ingredients in the pigment to the bottom of the bottle, and will even stain the inside of the bottle which in turn, causes the pigment to look different than it really is.

UNDERTONE - what the color looks like when it’s “spread-out” and how it appears on the skin. The most effective way to preview a color’s undertone is to perform a “draw-down” which involves spreading out the pigment over a white medium to view it from it’s most concentrated to lighter form.

You may see some inconsistencies in the bottle masstones and see social media posts where artists are concerned about variances, but rest assured that they have been carefully reformulated and matched to the best of our ability with Red 254. Variances in the drawdown between the old (with Red 210) and new formulation (with Red 254) have been kept to a minimum. During a transition like this there will always be an artist adjustment and relearning period, but rest assured we are working diligently to replicate the color, consistency, viscosity, and opacity.

Below are sample drawdowns of colors that have slight variances in masstone but are well-matched in undertone: Forest Brown, Fudge, Tres Pink, Sweet Melissa, Mallard, and Bronzer. Dark Forest Brown and Dark Fudge are two new colors in which drawdowns are displayed as well.

When comparing batches of bottle masstone colors to one another, know that you will see a variance. We encourage all users of the line to educate themselves on the pigments by performing their own draw-downs and adjusting the colors yourself to suit your preference. Perma Blend is a very user-friendly line and you can mix and modify the colors amongst any other colors in the Perma Blend line.

To further improve our ingredients, we are using a new preservative: benzyl alcohol. Benzyl alcohol is used as a bacteriostatic preservative at low concentrations in intravenous medications, cosmetics, and topical drugs. Preservatives protect products against the growth of bacteria, fungi, and yeast. Without preservatives, products could spoil and possibly harm you.

Benzyl alcohol is ONLY at 1% of our formula and has been proven and tested with stability testing to be sure it's working for our pigments. It also makes the colors a little thicker in consistency, something that we have been asked by our customers to do anyways. If you come across this situation and prefer your pigments thinner, you can dilute them to achieve the consistency you desire.

Also, we have taken another step towards higher standards and best manufacturing practices. By the end of this year of long, hard work, we have almost completed our ISO 13485 certification as a medical facility. This certification sets us above the rest as a safe and accountable manufacturer.

When you communicate with your customers regarding these changes and advancements, you will be able to inform them that Perma Blend is steadily evolving to become the safest, efficient and high-quality line in the market while still keeping a fair price point.

Thank you for your patience during this time. All of us at Perma Blend continue to value your support and feedback. The upcoming year is going to be our best year yet; we are excited to work together while continuing to provide industry-leading permanent cosmetics products!

Sincerely,

Lou Rubino, Anne Marie Rubino and the Perma Blend Team

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.